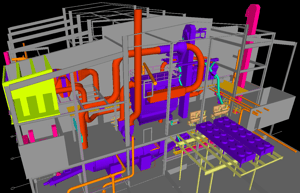

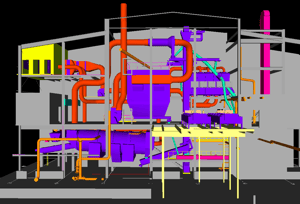

American Crystal Sugar Company B-Side Dryer/Cooler White Centrifugal Installation

Enhanced Drying and Cooling System Boosts Production and Reliability

This project involved upgrading a rotary drum dryer and cooler system to increase capacity and reliability. The new system included a rotary drum dryer, fluidized bed cooler, chiller systems, sugar screening machine, centrifugals, conveyors, and massecuite pumps. Safety improvements, such as fire sprinklers and dust collection, were added to meet NFPA and OSHA standards. Structural steel supports were installed, and the sump system was improved to reduce flooding. The new equipment was integrated into the factory's Delta-V control system. EAPC provided engineering, cost estimation, and construction support throughout the project.

Location:

East Grand Forks, MN

Sector:

Industrial Services:

Food and Beverage

Services:

Engineering

Box Description

Box Description