Industrial Services Projects

Ammonia Flare and Transfer System Design

Comprehensive Design Solutions Streamlines AECI Operations

EAPC designed a safer and more efficient ammonia offloading system to replace the complex, unreliable existing system. The new design supports ammonia delivery exclusively by tanker trucks equipped with offloading pumps, eliminating the need for compressors. A permanent flare was installed to handle venting operations, and a new transfer pump skid was added for emergency liquid transfer between storage tanks. EAPC provided comprehensive mechanical, electrical, and structural design services, including developing specifications, piping plans, flow diagrams, and P&IDs. The project, completed in March 2023, significantly improved safety and reliability at the Marston, Missouri facility.

Renville Cold Limer Heater Reconfiguration

Innovative Engineering Redesign Transforms Mixed Juice Heating Process

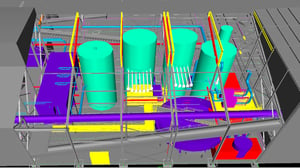

This project involved repurposing two unused plate and frame heaters for mixed juice heating and upgrading existing heaters with new plate packs. Comprehensive mechanical and electrical engineering services included 3D modeling to ensure compatibility with new piping layouts, modification and creation of P&IDs, and integration of automated valves for flow reversal. The upgraded system, utilizing multiple heat sources and existing clean-in-place piping, was designed to achieve higher juice temperatures, improving the overall process efficiency.

Carbonation Station

Streamlined Design Improvements Boost Beet Processing Efficiency and Output

A preliminary engineering study was conducted to redesign the washhouse layout and upgrade the carbonation system at this 13,000-ton-per-day facility. The project aimed to reduce sugar loss during beet washing by minimizing flume time and addressing carbonation system deficiencies due to increased slice rates. The new washhouse design incorporated a roller spray table and a new belt conveyor system, while the carbonation system upgrade involved installing new combination tanks, a prelimer, and a thickener. The study provided a comprehensive list of necessary equipment and upgrades, along with a total installed cost estimate to help secure funding.